Ultrasonic Ranging Sensor Installation Considerations

The Monnit ALTA Wireless Ultrasonic Ranging Sensor provides distance readings from the sensor horn to the surface immediately perpendicular. The sensor uses an ultrasonic pulse and calculates the distance from the perpendicular surface by calculating the time it takes for the ultrasonic pulse to return to the sensor horn. Please consider the following recommendations and instructions for a successful deployment when installing and operating the Ultrasonic Ranging Sensor.

Recommendations

- Install the horn as far away from the surface being measured as possible (a liquid that splashes or condenses into the sensor’s horn will cause errors or inaccurate readings.

- Inspect the sensor horn for liquid or material and clear it out to avoid errors or inaccurate readings.

- Ensure the liquid has a stable surface when the readings occur; otherwise, readings will not be accurate, and errors will occur. We recommend filling liquid tanks from the bottom to avoid waves that might affect the readings.

- Remove obstructions that will affect the ultrasonic pulse beam on the sides of the container or those introduced while the sensor takes a measurement.

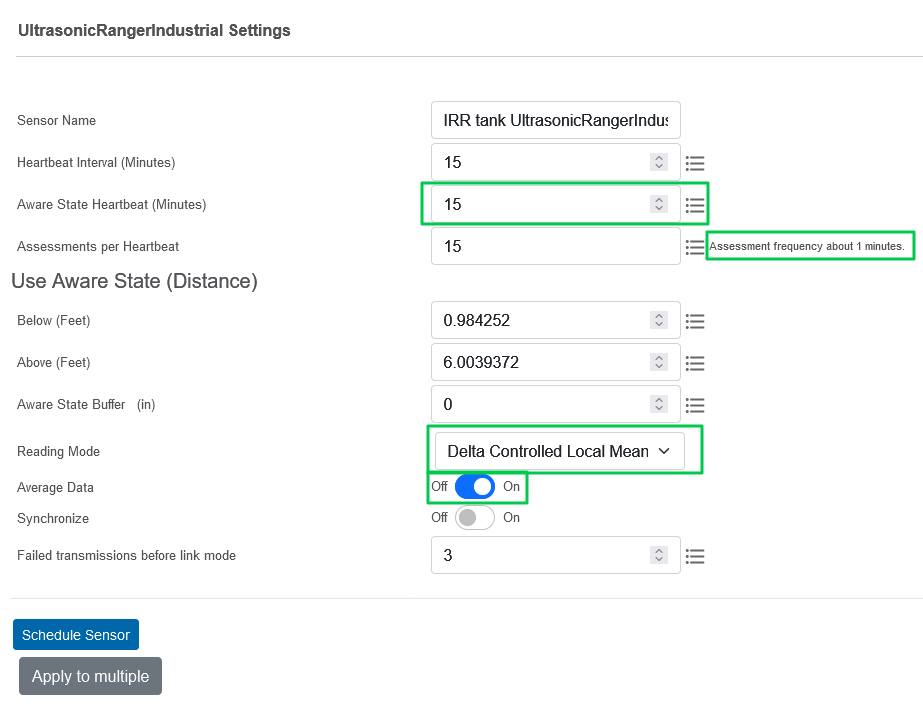

Consider using a different Mode

The Ultrasonic sensor offers several modes, which include maximum, minimum, and various averages applied to the signal. If the environment changes frequently (as in the case of moving water), one of these different modes may allow more reliable readings. To do so:

Note: The various modes are only supported on firmware 25.x.x.x and later.

Once this is done, the sensor will use the Assessments taken to calculate the values as per the selected Mode.

In the example below, the sensor will take a sample every 1 minute, and the reading the sensor delivers on its Heartbeat will be a delta-controlled mean calculated using the samples taken each minute.

Maximum/minimum distance

The Ultrasonic sensor has a maximum and minimum distance. You will observe a “Range Error” if the surface being measured is too far, too close, or there is some other sort of obstruction of the pulse or unstable surface detected.

Industrial Ultrasonic Sensor range

Minimum Measurement Distance: 20 cm (~3.9 in)

Maximum Measurement Distance: 750 cm (~157 in)

Sensor resolution: 1 cm (~0.39 in)

AA Enterprise Ultrasonic Sensor range

Minimum Measurement Distance: 10 cm (~7.8 in)

Maximum Measurement Distance: 400 cm (~295 in)

Sensor resolution: 1 cm (0.39 in)

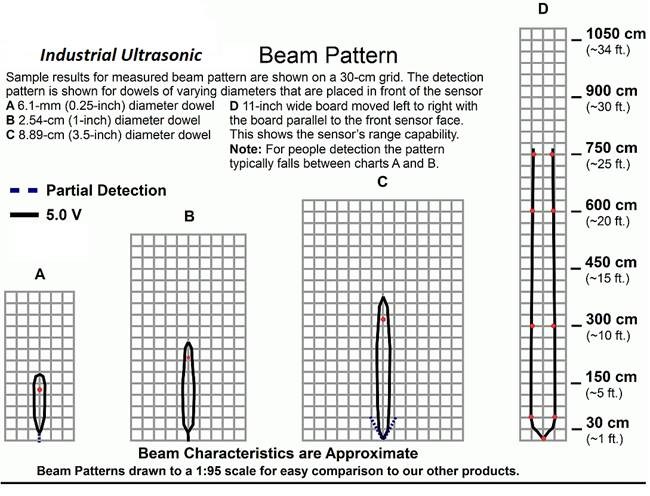

Pulse Width: For Enterprise/Commercial: Measuring Angle of 15 degree. At the maximum range of 4m (13 ft), The Beam with is “BW=Distance * tan(15/2) = 0.525m (1.7ft).

Industrial: Measuring angle of 10 degrees and a maximum distance of 7.5m (25ft), the sensor has a beam width of 0.65m (2.13 ft).

Unstable reading

You will see a reading indicating “Reading Unstable” if the pulse is not reliably returned to the sensor horn. It’s generally caused by a disturbed surface (like water in a tank filled from the top). The ultrasonic beam is less reliable when measuring the distance to unstable surfaces.

Calibration

The sensor will be delivered calibrated and will provide accurate readings. You may want to apply a different calibration to the sensor using the Calibrate tab in iMonnit. However, when testing the sensor, be sure to apply the default calibration.

Testing the sensor

To test the sensor:

- Set a more frequent (10 minutes or so) Heartbeat.

- Reset the sensor to the default calibration (Default tab in the Calibrate tab in iMonnit; ensure the sensor checks in and accepts the default calibration).

- Inspect and clear the horn of any debris or liquid inside the horn.

- Place the sensor horn 90 centimeters (~3 ft) directly perpendicular to a flat stationary surface.

- Observe the sensor report data over the next several Heartbeats. You should expect to see consistent readings within the resolution presented in iMonnit. Clear the path and remove obstructions to the beam if you see errors. If errors or erratic readings persist, please contact support@monnit.com.

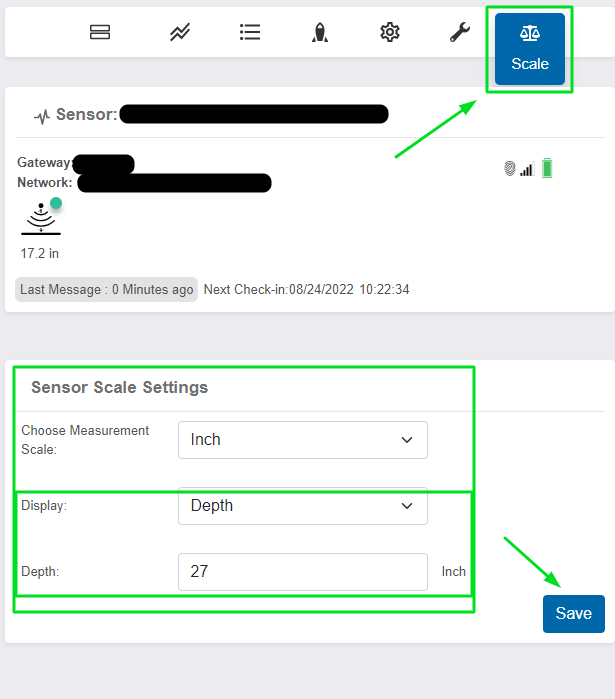

Depth configuration

The Ultrasonic sensor has the capability of displaying the depth of the substance in a container as opposed to the distance from the horn to the surface perpendicular to the horn. This can be useful if you prefer the readings of the sensor to report on how much liquid is left in a container, for example. As the liquid decreases in volume in the container, the depth will decrease.

This can be configured under the sensor’s Scale tab. There is a drop down which will allow you to select Depth. When depth is selected, there is a field into which you will input the distance between the horn of the Ultrasonic sensor and the bottom of the empty. You will want to be sure you enter this as precisely as possible to get accurate depth measurements.